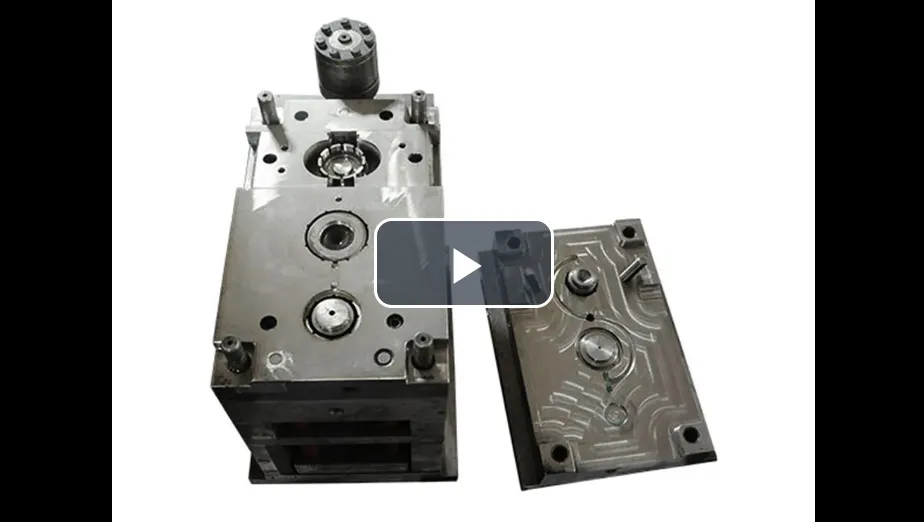

Khuôn lắp ống ba chiều PP-H

PP-H Three-Way Pipe Fitting Mold: Design, Functionality, and Applications The PP-H (Polypropylene Homopolymer) three-way pipe fitting mold is a precision-engineered tool designed for manufacturing high-performance pipe fittings used in industrial and residential piping systems. This mold plays a critical role in producing T-shaped or Y-shaped connectors that enable fluid or gas flow diversion in pipelines. Below is a detailed overview of its design, functionality, and applications. 1. Mold Design and Construction The PP-H three-way pipe fitting mold is typically made from high-grade steel, such as P20, H13, or stainless steel, to ensure durability and resistance to wear. The mold consists of multiple components, including: - Core and Cavity: These define the internal and external geometries of the fitting, ensuring dimensional accuracy. - Cooling System: Integrated channels facilitate efficient cooling to reduce cycle times and prevent warping. - Ejection Mechanism: Ensures smooth removal of the finished part without damage. - Venting System: Prevents air traps that could cause defects in the molded part. The mold is designed for high-pressure injection molding, ensuring consistent production of fittings with tight tolerances and smooth surfaces. 2. Material and Performance PP-H is chosen for its excellent chemical resistance, thermal stability, and mechanical strength, making it ideal for corrosive and high-temperature environments. The mold must accommodate PP-H’s high melting point (160–170°C) and shrinkage rate, requiring precise temperature control during molding. 3. Manufacturing Process The production process involves: - Material Preparation: PP-H pellets are dried to remove moisture. - Injection Molding: Molten PP-H is injected into the mold under high pressure. - Cooling and Ejection: The part solidifies, and ejector pins release it from the mold. - Post-Processing: Flash removal and quality inspections ensure defect-free fittings. 4. Applications PP-H three-way fittings are widely used in: - Chemical Processing: Resistant to acids, alkalis, and solvents. - Water Treatment: Safe for potable water systems. - HVAC and Industrial Piping: Handles high temperatures and pressures. 5. Advantages of the Mold - Precision: Produces leak-proof fittings with consistent quality. - Efficiency: Optimized cooling reduces cycle times. - Longevity: Robust steel construction extends mold life. Conclusion The PP-H three-way pipe fitting mold is a vital tool for producing reliable, high-performance fittings. Its advanced design ensures efficiency, precision, and durability, meeting the demands of modern piping systems across various industries.

Sản phẩm

Danh mục:

-

Khuôn lắp ống Tee nam CPVC

Phân loại của họ: Khuôn lắp ống CPVCLượt xem: 553Số:Thời gian phát hành: 2025-11-13 17:50:05Khuôn lắp ống Tee nam CPVCTên khuôn:Khuôn lắp ống Tee nam CPVCKhoang: 4 khoangKích thước khuôn: 48mm Thép khuôn:Đức2316 china2316 hoặc4cr13 cho khoang và lõiCổng: cổng trực tiếpCấu trúc khuôn: Xi lanh dầuĐộ cứng của lõi/khoang: HRC 40-45°degree sau khi xử lý nhiệt chân khôngMáy ép phun: 320 T Công ty TNHH khuôn mẫu Hongjin được thành lập vào năm 2002. Chúng tôi có nhiều kinh nghiệm hơn trong lĩnh vực khuôn lắp ống trong hơn 23 năm. Khuôn thoát nước sàn Cpvc được sử dụng thép không gỉ cho khoang và lõi khuôn.Chúng tôi rất mong được hợp tác lâu dài với bạn.Sau đây là thông tin chính để bạn tham...

Tin tức

Danh mục:

-

[industry news]Lợi ích của việc sử dụng khuôn lắp ống thoát nước PVC chất l...

2024-08-23 17:33:29

Trường hợp

Danh mục:

Video

Danh mục:

Tải về

Danh mục:

Không có kết quả tìm kiếm!

Tuyển dụng

Danh mục:

Không có kết quả tìm kiếm!

Sản phẩm được đề xuất

Không có kết quả tìm kiếm!

Whatsapp

Whatsapp Điện thoại

Điện thoại